It’s soggy, unpredictable, smells bad – and it turns up whether you want it or not.

Every year, millions of tonnes of food waste are generated across the UK from restaurant kitchens, households, supermarkets, manufacturers and hospitality. It’s constant, unavoidable, and until recently – mostly heading to landfill or incineration.

But everything changed on 31st March 2025.

New regulations under the Environment Act 2021 now mandate that virtually all UK businesses must separate and collect food waste for treatment via anaerobic digestion (AD) or composting. This isn’t voluntary. It’s the law. And it’s transforming the commercial landscape for biogas plants and operators across the country.

🧪 Fun fact: One tonne of food waste can generate enough biogas to produce roughly 400–600 kWh of electricity – enough to power the average UK home for 1–2 months.

For anaerobic digestion operators, this change isn’t theoretical – it’s already reshaping feedstock strategy, risk exposure, and plant economics.

Why Food Waste Matters Now

Food waste sits right at the intersection of Net Zero, circular economy policy, and waste compliance.

As regulation tightens and sustainability targets ramp up, AD has become the preferred route for organic waste recovery – converting unavoidable waste into renewable energy, digestate and carbon savings.

Why now?

🍽 Rising volumes of unavoidable food waste

📜 Stricter landfill and waste diversion rules

⚡ Demand for dispatchable, renewable gas

💷 Pressure to reduce reliance on costly energy crops

♻️ Incentives favouring waste-based biomethane (including GGSS)

🧪 Fun fact: Replacing just 10–20% of energy crops with food waste can increase total plant gas output – while reducing feedstock costs due to gate fees.

For many operators, food waste isn’t just attractive – it’s becoming central to plant economics.

The Pros: Why Food Waste Is So Attractive for AD

Despite its reputation, food waste is generally considered valuable feedstock. Let me breakdown carefully:

✔ high biodegradability and moisture

AD processes prefer wet and rich in easily degradable organic matter which microbes can efficiently convert to biogas.

✔ Policy-Aligned & Incentivised

As a true waste feedstock, food waste helps operators meet renewable content thresholds and align with sustainability schemes and ESG commitments.

✔ Abundant & Reliable

Unlike crops, food waste isn’t weather-dependent. Supply is steady, year-round, and often contract-backed.

✔ Gate Fees Improve Economics

In many cases, operators are paid to take it, dramatically improving plant margins compared to crop-based feeding strategies.

✔ Ideal for Co-Digestion

On paper, food waste looks like the perfect feedstock. In practice, this is often where operational challenges begin.

The Cons: Why Food Waste Can Be a Nightmare

This is where things get tricky.

⚠ Rapid Acidification

Food waste breaks down fast. Too fast.

Sudden VFA spikes can drop pH, inhibit methanogens and lead to full process failure.

⚠ Highly Variable Composition

One load might be fat-rich and energy-dense, the next watery and acidic. That variability makes stable feeding difficult.

⚠ Foaming, Scum & Mixing Issues

Greases, fats and proteins can cause foaming and stratification, reducing gas capture and stressing equipment.

⚠ Increased H₂S & Corrosion

Sulphur compounds drive higher H₂S levels, increasing gas cleaning costs and accelerating corrosion across plant infrastructure.

Most operators have experienced at least one of these issues – often triggered by a single bad or unexpected load.

So with all that risk – why do operators keep using food waste?

Why Operators Still Use Food Waste

Because when it works, it really works.

Operators often turn to food waste when:

- Crop prices rise or supply drops

- Waste-based biomethane targets must be met

- Plants want higher gas output per tonne

- Gate fees are needed to protect margins

- Long-term waste contracts offer revenue certainty

Food waste can make or break an AD plant – depending on how well it’s managed.

Why Food Waste Is So Valuable – Scientifically

Food waste isn’t just “organic waste”. It’s biochemically ready for methane production. That’s because it’s rich in: Fats (highest methane potential of any substrate), Sugars and starches (rapidly fermented), Proteins (high nitrogen).

When digestion is stable, food waste delivers some of the highest methane yields of any AD feedstock.

🧪 Fun fact: Food waste contains up to 3× more readily digestible carbon than cattle slurry – which is why it can produce 2-3× more biogas per tonne.

But that same chemistry is also where the trouble starts. So, the real question isn’t can food waste produce energy – it’s can we make it behave?

Making Food Waste Work: Enter CreChar®

With CreChar®, the answer is yes.

Let’s dig in 👇

CreChar® is our biochar engineered specifically for AD – designed to stabilise biology and unlock performance when using fast-fermenting feedstocks like food waste.

CreChar isn’t a feedstock replacement – it’s a biological stabilisation tool designed for high-risk, high-reward substrates like food waste.

How CreChar Helps

- Prevents Acidification & Process Upsets

CreChar moderates VFA accumulation and supports buffering capacity, reducing the risk of pH crashes during high-energy feeding.

- Protects and Strengthens Microbial Communities

Its porous structure provides a stable habitat for methanogens, improving resilience against feedstock variability.

- Boosts Biomethane Yield & Methane concentration (Quality)

By keeping digestion stable, CreChar helps convert food waste into more usable gas, with trials showing increased gas output and methane concentration.

- Cuts H₂S and Maintenance

CreChar adsorbs sulphur compounds, lowering H₂S levels, reducing odours and protecting CHP and upgrading equipment.

- Improves Operational Efficiency

Fewer crashes. Less downtime. More predictable performance – even with challenging or inconsistent food waste streams.

Together, these effects allow operators to push food waste harder – without pushing digestion biology too far.

From Problem Waste to Performance Feedstock

Food waste will always be messy, It will always vary and it will always challenge digestion biology. But with the right tools, it doesn’t have to destabilise your plant.

With CreChar®, food waste becomes what it was always meant to be:

A high-energy, policy-aligned, economically valuable feedstock – not a liability.

More stability.

More gas.

Lower risk.

Case Study: Stabilising Food Waste and Chicken Litter Co-Digestion

Take a look at the results from Case Study E, where the biogas plant used a feedstock blend of food waste and chicken litter, complemented by smaller contributions from other agricultural residues.

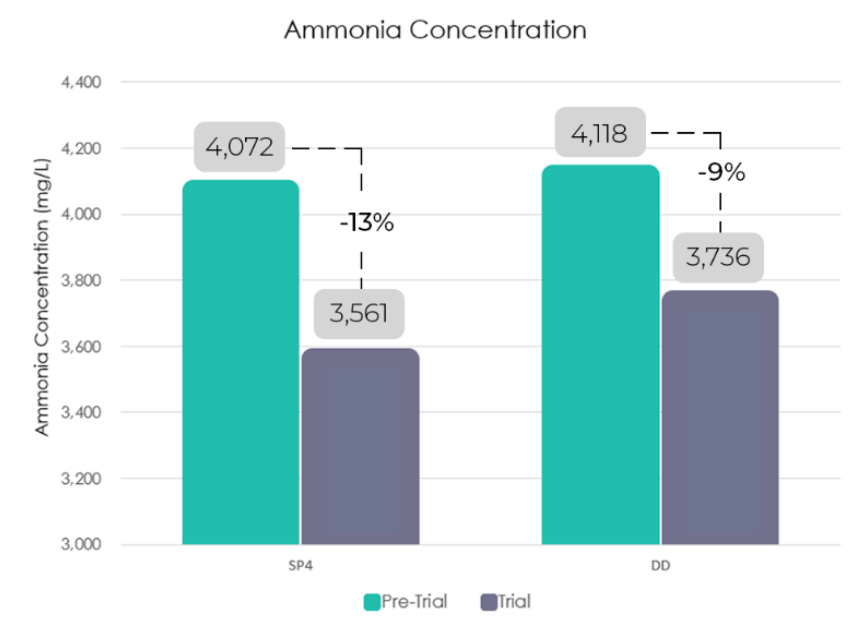

Over the six-month trial, the feedstock changed significantly – including variations in the chicken litter. Under normal conditions, such fluctuations would be expected to cause inhibition and biological stress. With CreChar, however, the digester remained stable throughout. Ammonia levels were reduced by 9-13%, helping to protect the biology of the plant.

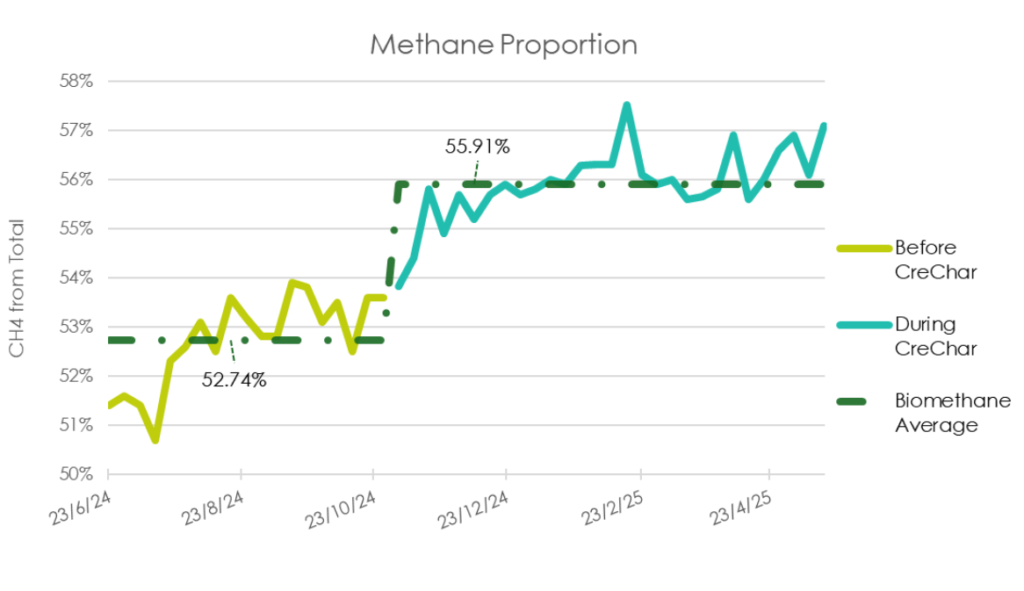

In terms of biomethane, the overall biogas generation rose slightly, by about 3%; but, an accompanying increase of 3-4% in methane concentration resulted in an 7-8% increase in total biomethane production. In effect, CreChar allowed the plant to extract more methane from a more challenging – but cheaper – feedstock mix.

Interested in a CreChar® Trial?

If your plant is using – or planning to increase – food waste, a CreChar trial is the simplest way to assess performance under your own operating conditions.

For further information on Crechar® and other services from Carbogenics please contact:

alana.mcskimming@carbogenics.com