Site F’s goal during the trial was to reduce feedstock costs by introducing a new mix, while also pushing the plant harder to improve efficiency and overall operational performance.

Crechar was added from the 16th of December 2024 until 15th June 2025.

OUR APPROACH

We run our large-scale operations, following a proven process to maximise the outputs and collect data relevant for performance monitoring. We require minimum input from the operator at the same time offering our expert advice to add further value.

The Carbogenics team assess the sites operational and chemical data filling in any gaps where necessary.

CreChar is supplied in 25 kg digestible bags which are added to the solid feed hopper daily, resulting in no disruption to normal plant operation.

FEEDSTOCK ANALYSIS

The trial period marked a significant and risky shift in the plant’s feedstock strategy. Previously, the system relied on a stable, fibre-heavy diet. The new approach, aimed at boosting output and reducing feedstock costs, introduced a more volatile, energy-rich mix. This shift created several potential risks for the digestion process:

- Decreased Fibre Inputs: The trial saw a reduction in materials like grass silage and oats, which provide structural stability and a steady release of biogas.

- Increased High-Sugar Substrates: The addition of highly fermentable sugars from fodder beet and large volumes of Whey Permeate created a high risk of rapid acidification. This can lead to a dangerous accumulation of volatile fatty acids (VFAs), potentially crashing the digester.

- Nitrogen-Carbon Imbalance: A continuous high-volume use of poultry litter introduced a slight increase in nitrogen, which, without sufficient carbon from the feedstock, could lead to a C/N imbalance and ammonia toxicity.

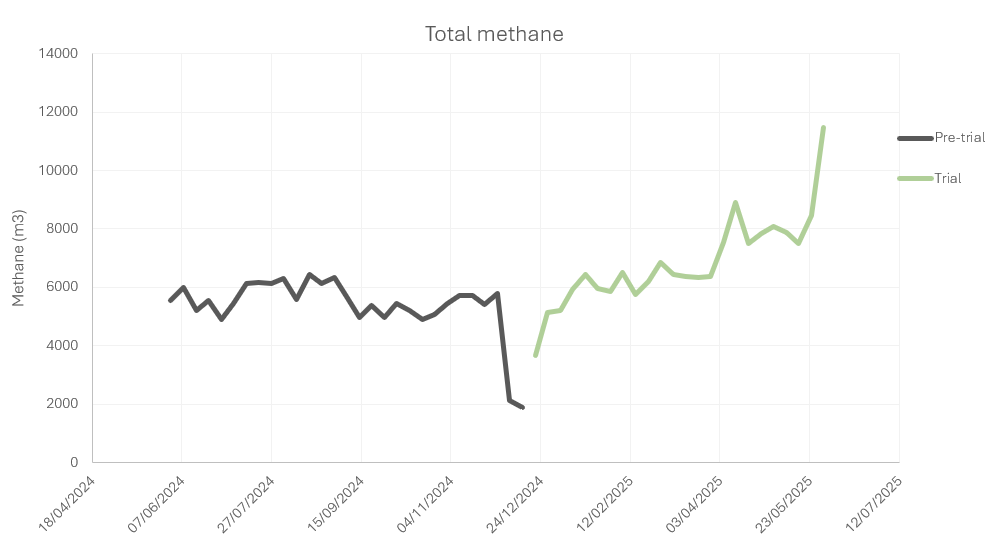

BIOGAS & METHANE

The strategic shift in feedstock, a move that would typically destabilise a digester, was made possible by CreChar’s robust buffering capacity.

The plant’s biomethane yield responded directly to the quality of the new substrates, peaking at approximately 180 m³ CH₄/t with the fodder beet and grain mix. Although the introduction of Whey Permeate caused a temporary drop in yield, the system quickly recovered. The overall result was a 14% uplift in biomethane, which plant operators credit to CreChar’s ability to prevent the instability that would have otherwise caused a system crash.

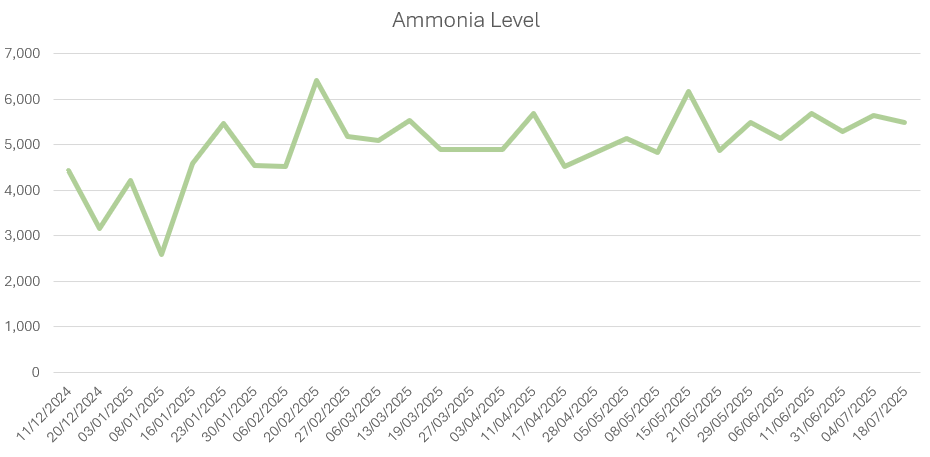

AMMONIA REDUCTION & PLANT STABILITY

One of the most critical challenges was managing high nitrogen inputs from continuous poultry litter use. Ammonia concentrations (DD values) remained relatively stable despite significant protein loading.

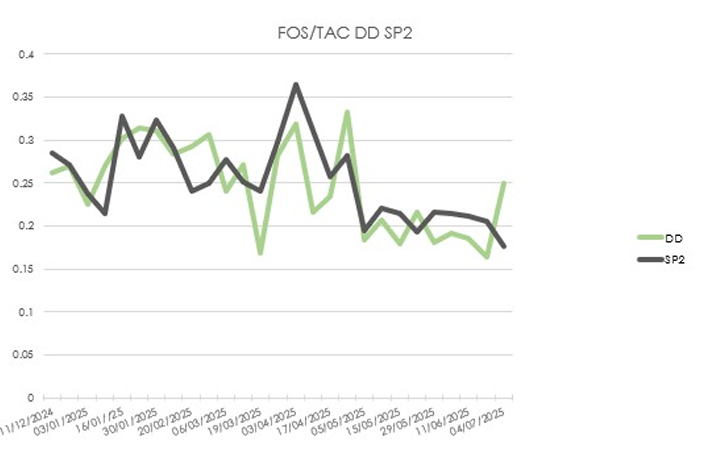

Despite these volatility risks, the plant did not experience the expected microbial collapse or severe acidification. Instead, CreChar’s stabilising role was evident in the plant’s FOS/TAC and pH data. The FOS/TAC ratio consistently stayed below 0.3, and the pH remained stable between 7.5 and 8.3. This demonstrates that CreChar provided the necessary buffering capacity to prevent acidification and VFA accumulation. The digester’s ability to self-correct and maintain these stable conditions, even during critical periods, is a testament to CreChar’s efficacy in buffering the system against the inherent risks of a volatile feedstock diet.

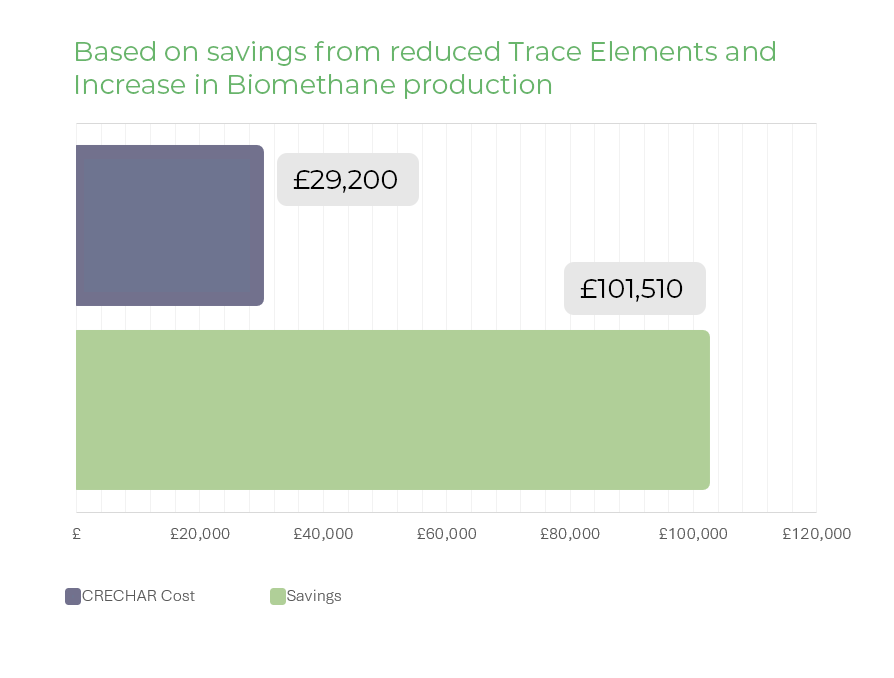

RETURN ON INVESTMENT AND COST SAVINGS

The trial yielded clear financial benefits, primarily from the savings on chemical additives and increased revenue from biogas.

- Chemical Cost Savings: The site reduced ferric dosing, which was costing approximately £2,250 per month pre-trial. Stopped trace element dosing reducing costs by £20,000 per annum.

- Revenue from Biogas: The 14% uplift in biomethane production translated directly into increased revenue from the CHP (Combined Heat and Power) system of £41,255 which would equate to £81,510 per annum.

SUMMARY

The overarching goal of the trial was to allow for increase in organics loading on the front end of the system as well as increasing Poultry Litter input. This saw the potential risks of ammonia inhibition, organic overloading rate as well as potential process instability. From the feedstock variation and increased feed rate ability, the site saw a 30% reduction in feedstock cost and direct p/m3 and p/kwe reduction, increasing profitability. CreChar provided the stability to handle the inherent risks previously discussed.

“I’d say one of the best outcomes we saw from CreChar was that we completely stopped our trace element dosing and managed to maintain process stability and reduce a pre-trial cost of £20k per annum.” – AD Plant Operations Manager

SUMMARY & CONCLUSION

The 6-month trial successfully demonstrated that CreChar is a highly effective stabilising and buffering agent for anaerobic digestion. It enabled the plant to optimise its feedstock strategy, increase biomethane production, and reduce operational costs.

- Enabled aggressive feedstock transitions without system instability, mitigating the risk of rapid acidification and VFA accumulation.

- Maintained stable ammonia, pH and FOS/TAC ratios despite significant digestive shocks.

- Acted as a viable and cost-effective support for H₂S control by reducing ferric dosing enabling additive savings for both ferric and trace elements

- Facilitated a 14% uplift in biomethane by enabling the use of energy-rich substrates, resulting in a potential annual revenue increase of £81,510

These improvements translated into meaningful financial outcomes. With increased efficiency, reduced feedstock and digestate costs, and higher-value renewable energy generation, the modelled savings for a comparable plant amount to significant sums annually, even after accounting for the cost of CreChar.

Perhaps most importantly, the trial shows how CreChar helps operators future-proof their plants. As subsidy schemes and grant support reduce over time, long-term profitability will increasingly depend on higher efficiency, lower operating costs, and the ability to handle volatile feedstock markets. By delivering greater gas yields and more stable operations, CreChar offers a clear pathway to keeping AD plants competitive and profitable in a subsidy-light future.

CONTACT

For further information on Crechar® and other services from Carbogenics please contact:

Lidia Krzynowek: (COO and Co-Founder)

lidia.krzynowek@carbogenics.com