Site Information

Site E is a well-run plant, already operating at around 90% efficiency. Despite this, the operator was keen to investigate solutions to increase efficiency for a new gas to grid site under development, using this trial to test CreChar’s potential for the future plant rather than immediate gains at this one. Crechar was added from the 18th of October 2024 until 30th March 2025.

Our Approach

We run our large-scale operations, following a proven process to maximise the outputs and collect data relevant for performance monitoring. We require minimum input from the operator at the same time offering our expert advice to add further value.

The Carbogenics team assess the sites operational and chemical data filling in any gaps where necessary.

CreChar is supplied in 25 kg digestible bags which are added to the solid feed hopper daily, resulting in no disruption to normal plant operation.

Feedstock Analysis

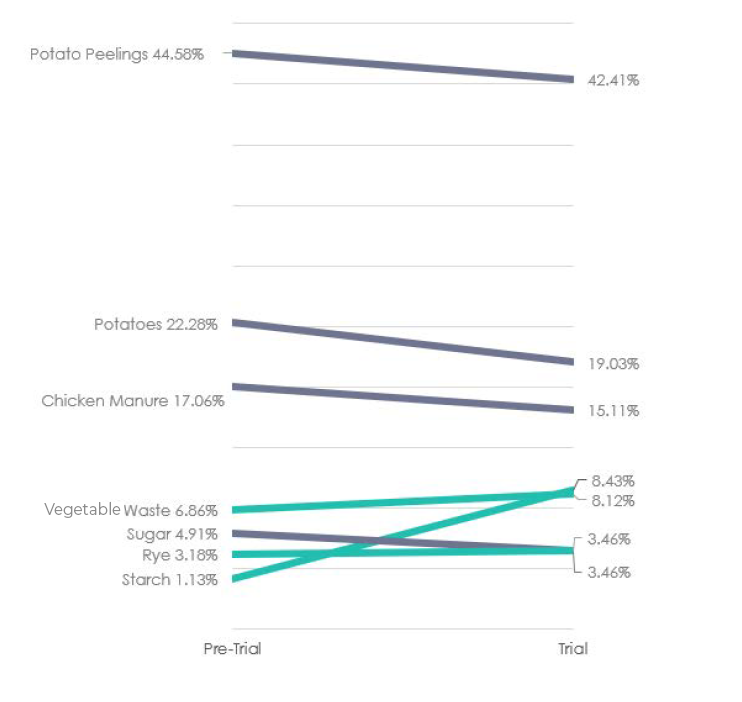

During the trial, the operator introduced a new feedstock mix – one of the more significant changes was the large increase in liquid starch. This shift increased the total feedstock volume by around 10%.

However, these additional cheap feedstock materials are less energy-dense and considered less desirable from an energy perspective. Therefore, overall biogas potential for the site remained unchanged.

In theory, the same amount of biogas should have been produced. However, with the addition of CreChar, the digester achieved an increase in Biomethane output, amongst other benefits.

Biogas & Methane

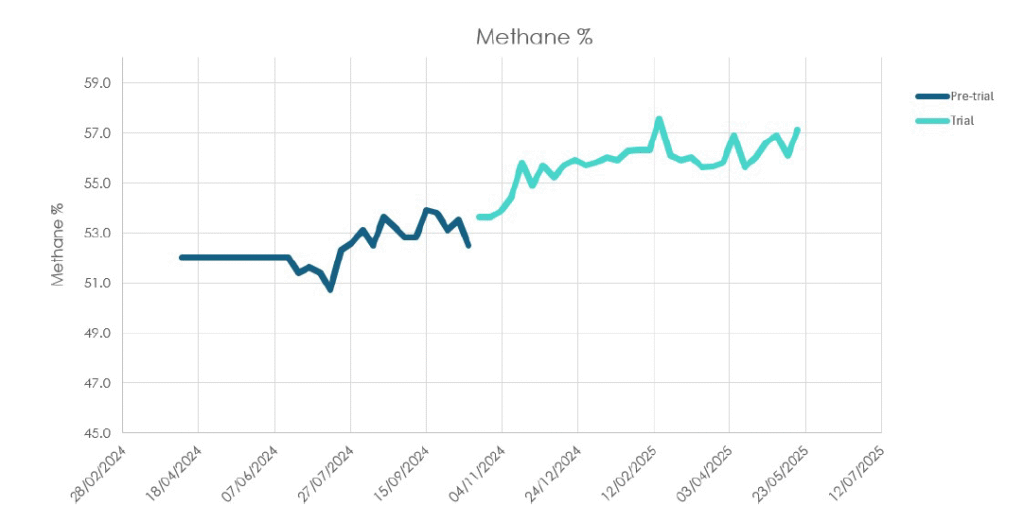

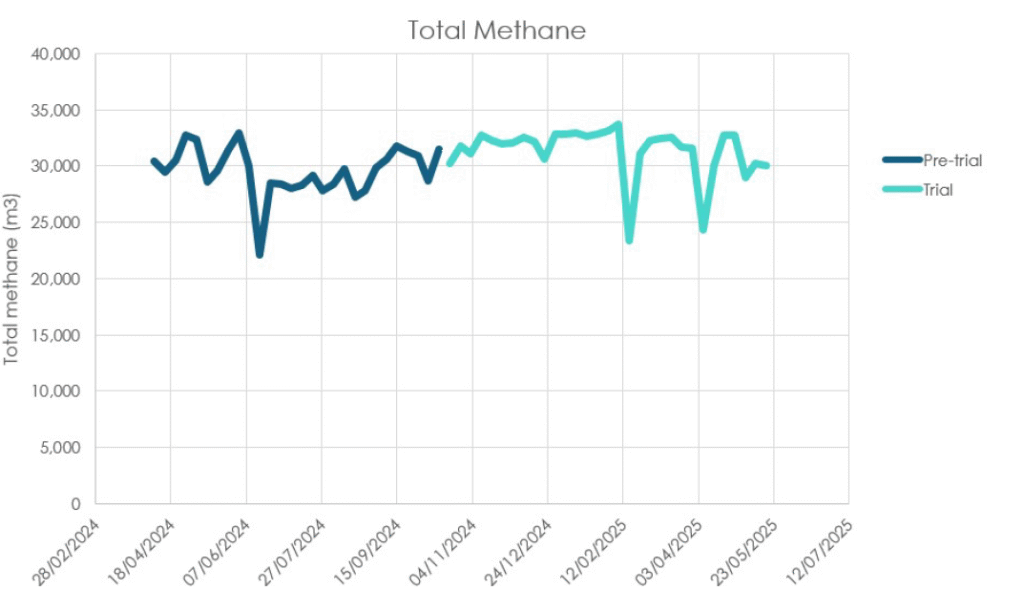

Although the biogas potential of the feedstock mix remained unchanged, the actual performance of the digester told a different story.

With CreChar, the plant achieved:

· 3-4% increase in methane concentration

· 8% increase in total biomethane yield

The 3-4% rise in methane concentration and a small increase in overall biogas yield meant that overall biomethane output increased by 8% compared with the pre-trial baseline. This demonstrates that, even with a weaker and cheaper feedstock mix, CreChar enabled the plant to achieve a higher-quality gas and significantly greater biomethane yield.

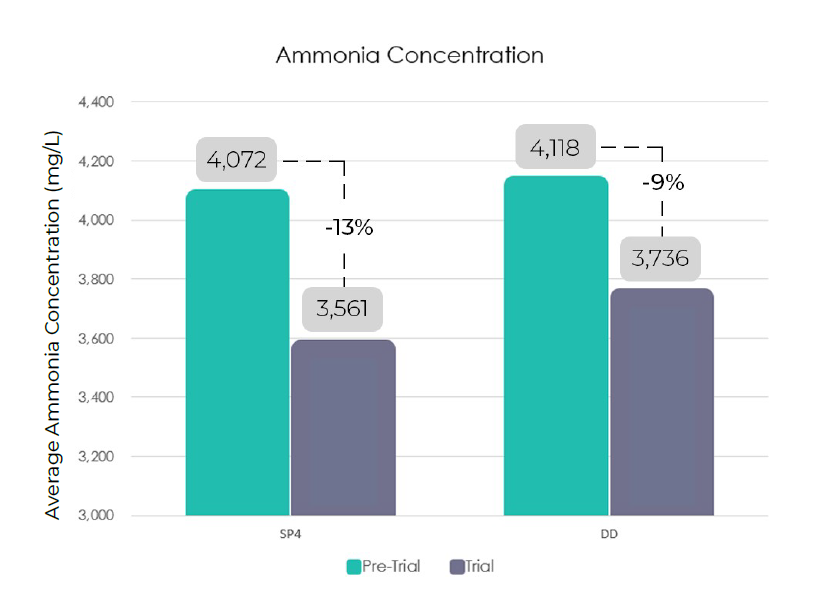

Ammonia Reduction & Plant Stability

Over the six-month trial, the feedstock mix changed significantly and at times quite rapidly – including variations in chicken litter and the introduction of more liquid waste. Under normal conditions, such fluctuations would be expected to cause inhibition and biological stress but the digester remains stable (as shown in the FOS/TAC Graph below).

With CreChar, however, the digester remained stable throughout. Ammonia levels were reduced by around 10%, with peaks smoothed out, helping to protect the biology of the plant.

This stability gave the operator confidence to push the system further and be more innovative with feedstock choices, knowing that the process could handle change.

Return on Investment and Cost Savings

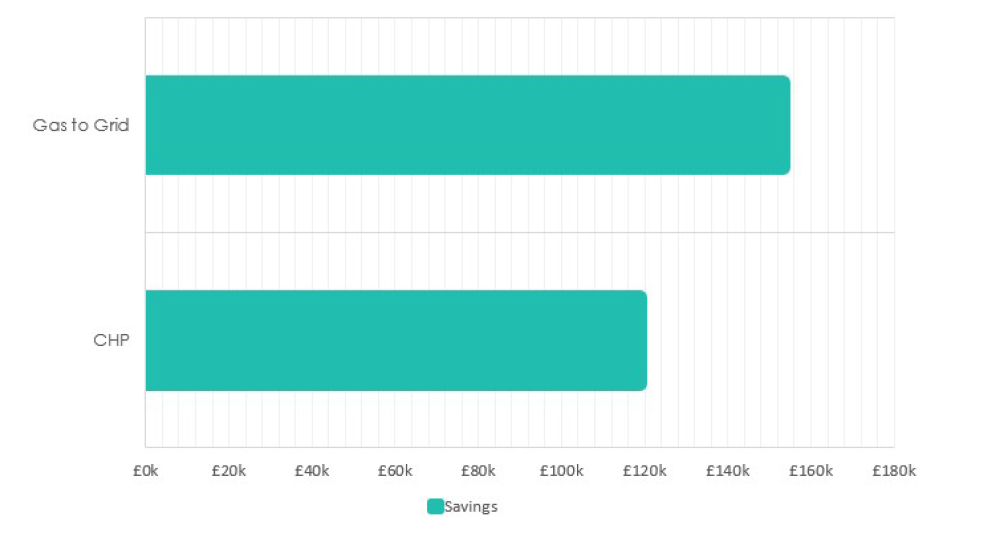

By improving biomethane yields, CreChar boosts overall output, which directly increases the value of renewable energy exported. During the Trial period the site created an additional 851,696 Kwh – this represents a 10% uplift. The accompanying graph models this uplift using current tariff assumptions – £0.1/kwh / Fit 0.085/ kwh and £ 0.05/kwh / GGSS 0.4/kwh. From these calculations a CHP plant could increase revenue by £118,810 and a gas to grid by £153,304 per annum.

Feedstock Cost Savings

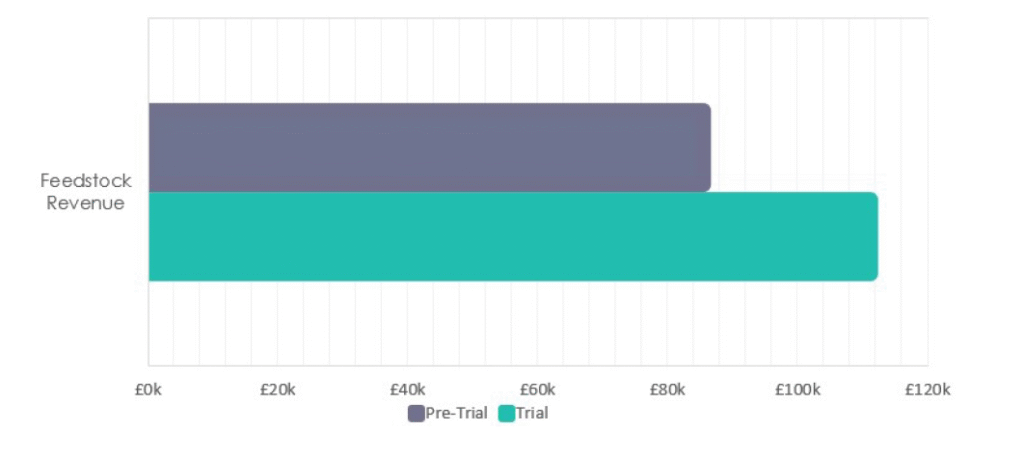

The site is in a unique position thanks to its access to low-cost and even free feedstocks, meaning the immediate financial benefits from reduced feedstock costs are less pronounced here than they would be for their future gas-to-grid operation.

Therefore, CreChar could generate significant feedstock savings for operators that need to reduce their feedstock costs to maximise their revenue. This allows operators to process more diverse, lower-cost inputs more flexibly and frequently without compromising digester stability. The accompanying graph models these potential savings under a normal feedstock cost scenario. In a like for like scenario this graph displays a saving of £25,734 throughout the duration of the trial.

Summary & Conclusion

This six-month trial demonstrates how CreChar can deliver tangible performance and financial benefits for anaerobic digestion operators. Despite changes in feedstock mix – including the introduction of cheaper, lower-value materials – the plant not only maintained stability but achieved:

· 3–4% increase in methane concentration

· 8% uplift in biomethane yield

· 10% reduction in ammonia levels, supporting smoother biology

· Greater process resilience, enabling the operator to adopt more flexible

feedstock strategies

· Potential feedstock savings of £25,734

· CHP revenue increase of £118,810 and a gas to grid by £153,304 per annum

These improvements translated into meaningful financial outcomes. With increased efficiency, reduced feedstock and digestate costs, and higher value renewable energy generation, the modelled savings for a comparable plant amount to significant sums annually, even after accounting for the cost of CreChar.

Perhaps most importantly, the trial shows how CreChar helps operators future-proof their plants. As subsidy schemes and grant support reduce over time, long-term profitability will increasingly depend on higher efficiency, lower operating costs, and the ability to handle volatile feedstock markets. By delivering greater gas yields and more stable operations, CreChar offers a clear pathway to keeping AD plants competitive and profitable in a subsidy-light future.

Contact

For further information on Crechar® and other services from Carbogenics please contact:

Alana McSkimming

alana.mcskimming@carbogenics.com